Alright guys, finally got some time to work on my 332ti project. Just when I thought things were getting ready to come together, I ran into a little problem. Now this isn't an s52 specific problem as I'm sure m42/m44/m50/m52/s50 and s52 engines have the same design in regards to timing the cams.

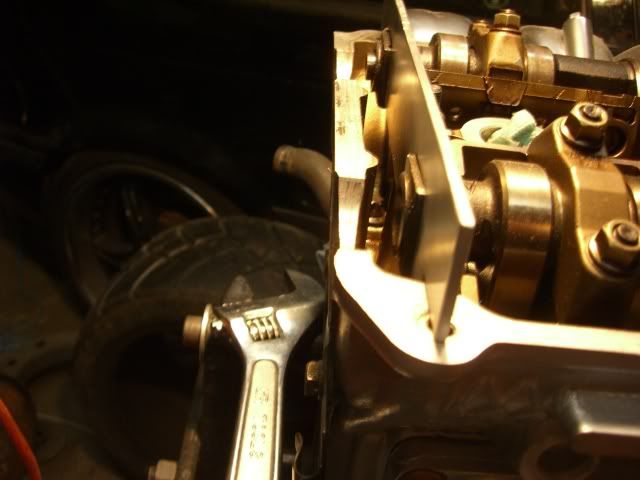

First, I made this tool:

It's supposed to fit over the square blocks on the back of the cams and rest on the head to ensure the cams are perfectly level:

The crankshaft is set and locked at TDC. The tool I made is exactly to spec in accordance with the manual(haynes manual has a template). I've checked my tool and I'm certain that it's square and precise.

Now here's my dilema. When I put the tool on the cams, It doesn't fit precisely. Upon closer inspection, I noticed that the blocks on the back of the cams aren't even square! The tool won't sit flush on either side of the head where it's supposed to rest on because the corner of the cam blocks hit the inside of the tool. The exhaust side comes close, but the intake side needs another 1/4" or so before it even meets the head. It appears that the sides of the blocks fit perfectly into the tool, but the tops of the blocks(with the holes drilled in them) are cut diagonally/crooked. This means that all of the vertical edges of the blocks are in line with eachother, but the horizonal edges are nowhere close to being level. The reason is obvious, the blocks are not square. I dunno what to do now. I know Budget76 used a straight edge to level his cams, but I don't think that method will work on mine. Any suggestions?

Also FWIW, I didn't move the exhaust cam at all when installing the tool. The intake cam needed to rotate about 1/16 of an inch counter clockwise to slide the tool onto it. I ran the engine for about 30 minutes before I pulled it. Ran smooth, a little ticking but I attributed that to it sitting for over a month and the previous owner running 0 weight oil. So if a straight edge across the top is the proper way to time them, that would mean that the timing was way off to begin with, which I don't think is even possible. I think if I used a straight edge across the top of the blocks and bolted everything down, it would bend the crap out of my valves.