» Site Navigation » Site Navigation | | |  » Recent Threads » Recent Threads | | | |  |  |  | |  07-23-2009, 09:19 PM 07-23-2009, 09:19 PM | #1 | | Member Join Date: Mar 2008 Location: iowa Posts: 79 |  Timing Tools: necessary to use?????? Timing Tools: necessary to use??????

Ok guys its been awhile since i was on but good news my car is home from colorado. I tore it down and sure enough the head was cracked at the exhaust seat to the water jacket. Now I have my other head i bought off a member last year valve job complete with a port and polish. My ? is do I have to have the camshaft alignment tool to reinstall my sprockets to the cam also supposed to use a crank lock tool that installs into the flywheel. Now Im a mechinic by trade and i understand the valve clearance on this M44 is nill. Do i have to use the tools or taking my time can i do it without them. And i live in iowa does anyone live close to me that has the tool i can borrow. THanks guys im die ing to drive my car it looks so sad sitting at my shop. Its begging to be drivin. LOL |  |  |  07-23-2009, 10:48 PM 07-23-2009, 10:48 PM | #2 | | Senior Member Join Date: Aug 2006 Location: Central NJ Posts: 2,440 |

You should be able to get the whole cam set for around $100. I saw it while looking for stuff on repairing the VANOS system of the M52/S52 motors. |  |  |  07-24-2009, 04:30 PM 07-24-2009, 04:30 PM | #3 | | Member Join Date: Mar 2008 Location: iowa Posts: 79 |

so your saying i really should attempt to use a tool of some sort to align the cams. I suppose i could just make one. thanks for the input guys ill post when its running then its time to find black leather seats from a member... mine are cloth. i cant wait to drive her!!!!! |  |  |  07-24-2009, 05:16 PM 07-24-2009, 05:16 PM | #4 | | Member Join Date: Mar 2008 Location: iowa Posts: 79 |

i was just asking if anyone did not use the tool and it worked. Im a ASE master mechanic and i know the valve clearance is dam near 0. I have done plenty of jobs not using the tools and being very anal in my installations. I just want my car this weekend and i have not purchased the tools. I will make my own instead just cause i want to drive it this weekend. i have been without her for over a year. she has been in durango colorado at my moms thats where the head cracked. So what im saying is im more than qaulified to do the work i just was asking a simple ?  But thanks for your input  |  |  |  07-24-2009, 05:18 PM 07-24-2009, 05:18 PM | #5 | | Senior Member Join Date: Aug 2006 Location: Central NJ Posts: 2,440 |

The valve clearance is negative. If the cams are off, the valves WILL hit the piston. |  |  |  07-24-2009, 08:17 PM 07-24-2009, 08:17 PM | #6 | | NOBODY F's with the Jesus Join Date: Oct 2006 Location: Ventura California Posts: 7,824 |

I've deleted my posts. Find someone else to help you then  |  |  |  07-24-2009, 08:34 PM 07-24-2009, 08:34 PM | #7 | | Senior Member Join Date: Aug 2006 Location: Central NJ Posts: 2,440 |

I don't think he meant to offend you... If not for him, could you re-post your info so when I rebuild my 2nd motor I know how to align my camshafts? |  |  |  07-24-2009, 09:11 PM 07-24-2009, 09:11 PM | #8 | | Member Join Date: Mar 2008 Location: iowa Posts: 79 |

WOW someone woke up on the wrong side of the bed! And i was just telling my co workers how cool the people on this site are. I took what you said wrong because you insulted my abilites i was just asking ?'s. Chill dude! I just want my car running this weekend yeah i could wait and order the timing kit but i want to drive my car. I understand its not my first rodeo you know what i mean. I said thanks for your help and info and you flip me off nice for being a site supporter. interesting. anyways thanks guys ill keep you posted on my progress. and chill cooljess76 dam dude WTF? |  |  |  07-24-2009, 09:54 PM 07-24-2009, 09:54 PM | #9 | | NOBODY F's with the Jesus Join Date: Oct 2006 Location: Ventura California Posts: 7,824 |

Alright look man, first you asked if you could do this job without the tools. I said I made my own using a template out of one of the manuals and post a link to my thread. You come back and say "so your saying i really should attempt to use a tool of some sort to align the cams..." I say yeah you need the tools, it's not the type of job you want to eyeball and call it good, maybe you should take it to a shop and I wondered if you were even capable of doing the job based on the questions you were asking. Then you come back with your "Oh, well I'm an ASE Master Mechanic, I'm more than qualified to do this job..." Of course you need the tools! The cams aren't going to magically time themselves. I don't care if you're an "ASE Master Mechanic", you can't eyeball this job and expect it to be right. The fact that you claim to be a master mechanic, but you come here asking if you need tools to align your cams and you've done plenty of jobs without tools but you're sooooo anal about your installations... c'mon man, give me a break. If you were "so anal about installations" and a "master mechanic" you wouldn't be asking if you need the tools, you'd know better. If you were here asking for torque specs or something, I'd understand because the Bentley manual has them all screwed up. I was just offering help. Yeah, I made my own tool. There's a template on 2B-4 of the haynes manual. Here's a thread I started: http://www.318ti.org/forum/showthread.php?t=26315 One member told me he used a straight edge across the top of the blocks at the ends of the cams. He said his car runs fine. If you look at the pictures of my cams in the link I posted, you'll notice that they're nowhere near square! If I were to use a straight edge and tighten everything down, they would have been off by 20 degrees! After making the tool according to the template, I finally realized that the tops of the blocks weren't even precisely machined, it was the sides of the blocks that were machined to fit square into the tool, thus meaning that the sides of the blocks were supposed to be square with the surface of the head AND NOT THE TOPS. That little bit of misinformation could have very easily costed me my engine. Had I took that members advice and used a straight edge to align my cams, I'd be replacing my s52 right now. That's why I post here, to try to help people. But when I get these so called "Master Mechanics" and "Engineers" telling me some BS, yeah I get a little edgy.

Last edited by cooljess76; 07-24-2009 at 10:13 PM. |  |  |  07-24-2009, 10:09 PM 07-24-2009, 10:09 PM | #10 | | Senior Member Join Date: Aug 2008 Location: Raleigh/Charlotte, NC Posts: 1,233 |

I agree with Jess, you should use the tools, BUT for what its worth, I did not use the tools and I use a straight edge and My car runs fine. I used the pelican parts method, then spun the motor with the cams out to TDC, then realigned the camshafts so the valves matched TDC and rebolted them down. You have to be VERY careful. I gave the motor a few spins by hand before cranking it up just to make sure I had no valve on piston contact.

I think you could get away with without the tools on a non-vanos motor (m42/44 and some m50s but I would not even try on a vanos motor. __________________ -Jeff

|  |  |  07-24-2009, 10:31 PM 07-24-2009, 10:31 PM | #11 | | Member Join Date: Mar 2008 Location: iowa Posts: 79 |

its cool man its all good im using your link to make my own tool this weekend. sorry if i was edgy its just i want to drive it bad can you blame me lol. i understand what you meant and what your saying. Its not a hard job to do and i could probably do it without the tools but i feel much better making my own to hold them in place so they dont move when im installing the spockets and such. I just get jumpy when people say things that get under my skin you appear to be the same way. but i will take your advice to heart and make my own tools. I just want to drive her LOL have a good weekend chill drink some beers or something ha ha. And thanks again for your input! Oh by the way i like to get all my ducks in a row before i start shooting and if that means coming on to a forum and asking ?'s (even stupid ones) then oh well i asked for advice and not on my ablities to do the job. Yeah i was probably going to do it my way anyway but thats what this site is for asking ?'s not getting rude answers. Long story short is i appreciate your input and i will let you know how it goes.

Last edited by bmwgeoff; 07-24-2009 at 10:38 PM. |  |  |  07-24-2009, 11:43 PM 07-24-2009, 11:43 PM | #12 | | Senior Member Join Date: Apr 2006 Location: Oxford, Ohio Posts: 868 |

If I were you I would use the tools. I have a set of the tools which are custom made. The cam locking tool is different than this one and looks more like the BMW tool. You should also have a flywheel lock and a rigid chain tensioner. Take a look in the Knowledge base, I posted drawings there so you can see what they look like. I have been loaning these tools out for free. Someone expressed interest in using the tools next. I have sent him a message asking if he still needs them. If I don't hear back from him by Tuesday, they could go to you next. If not you can get in line after him or make your own. PM me for details. Here is the link to the KB article: http://www.318ti.org/forum/showthread.php?t=11334 |  |  |  07-25-2009, 02:48 AM 07-25-2009, 02:48 AM | #13 | | NOBODY F's with the Jesus Join Date: Oct 2006 Location: Ventura California Posts: 7,824 |

You see what I'm sayin, Xenocide and Budget76 both did theirs using a straight edge instead of the specified tool. While the car may run fine, it's still not timed and adjusted to spec. That's just not acceptable in my mind. Sure there's a little margin for adjustment, some people purposely advance their cams a couple degrees to increase performance, but using a straight edge across the top is not how one would go about doing that. Usually when people do this, they use a gauge to measure valve clearance so they have even numbers across the board and everything is set to maximum performance. As you can see in this pic, the cam blocks are not perfectly square:  ^^^notice the angled gap at the top? My tool is perfectly square and the cam block obviously doesn't match at the top. That's okay though. I figured out that the only thing that matters is that the sides of the block are square with the head. How did I come to that conclusion you ask? Well because the sides of the blocks have been machined by the factory to accept the tool. The tops of the blocks are still rough from the factory cast. So if you use a straight edge across the top to align the cams, there's no way that it can be right. Unless your blocks were casted perfectly square, which I highly doubt because if they were BMW wouldn't have needed to machine the sides of the blocks. This is what the tool looks like, I deviated from the template by making my block cutouts deeper so the tool would sit flush on the head profile:  This is what I mean by machined edge. The vertical sides of the blocks were machined by the factory. You can clearly see that the sides are nice and smooth while the top and bottom sides are rough. Obviously, it was designed this way so the tool would fit perfectly on the blocks:  Notice how the tool, when cut perfectly to spec and placed on properly aligned cam blocks, sits flush on the head:    So my point is that people here will tell you that you can use a straight edge to align your cams, but after seeing my pics I hope that you have enough sense to know that it DOES MATTER regardless if their cars are running good or not. Look at those gaps on top of my cams and imagine if I would have just used a straight edge across the top, how bad my timing would be... I may not be a certified BMW Technician, but trust me, I do know what I'm talking about. I can't make my point any more clear. Cam timing is very serious stuff!

Last edited by cooljess76; 07-25-2009 at 03:09 AM. |  |  |  07-25-2009, 03:20 AM 07-25-2009, 03:20 AM | #14 | | NOBODY F's with the Jesus Join Date: Oct 2006 Location: Ventura California Posts: 7,824 |

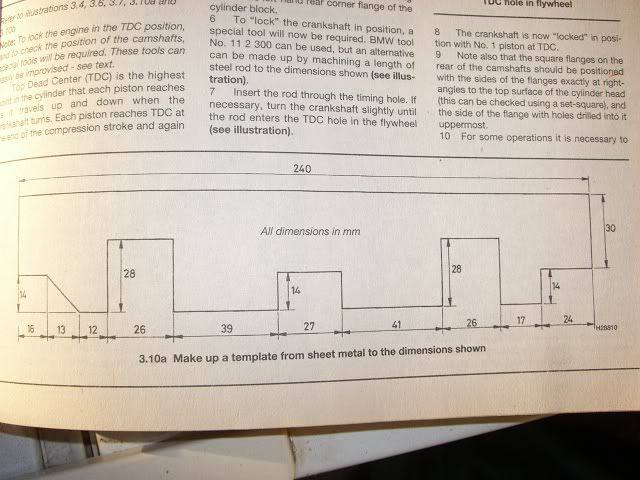

Just remembered that the template on page 2B-4 of the Haynes manual is for the 6cyl engines(Xenocide, Budget76 and myself have 6cyl swaps). There is however a template on page 2A-3 of the Haynes for 4cyl engines:  |  |  |  07-27-2009, 08:05 PM 07-27-2009, 08:05 PM | #15 | | Member Join Date: Mar 2008 Location: iowa Posts: 79 |

Ok all done. Job was nice and easy. I used your advice and made my own tool out of sheet metal. I used a cut off wheel to get it close then used a file to get my dimensions perfect. I test fitted it on my cracked junk head. Now I made the tool just like the drawing and I see what you mean by making the cam slots longer so the tool fits flush on the cylinder head surface. Mine didnt sit flush but the distance to the surface was equal. As for that bingo from start to finish It took about 6 hours and I took my time. I used a dial indicator on #1 piston to set it at TDC then made a paint mark as a reference to make sure the crank doesnt move on me. Then using the tool I installed the cam sprockets and chain tensioner then tightened spocket bolts. Car purrs like a kitten and I alsready put 100 miles on it just yesterday. I took pics with my phone as soon as I figure out how to send them via email ill post for your enjoyment LOL. I didnt mean to be a prick its just i know im a good mechanic and all I wanted was more input. But thanks alot for your help.  |  |  |  | |

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | | |

Posting Rules Posting Rules | You may not post new threads You may not post replies You may not post attachments You may not edit your posts

HTML code is Off

| | |

|