» Site Navigation » Site Navigation | | |  » Recent Threads » Recent Threads | 1999 M3 Swap 09-07-2023 10:10 PM 05-02-2024 08:18 PM 6 Replies, 330,330 Views | | | |  |  |  | |  08-20-2013, 03:02 PM 08-20-2013, 03:02 PM | #16 | | Member Join Date: Jun 2008 Location: Utah Posts: 62 |

The strut shaft extends through the bottom and is secured with a nut, this holds the strut insert axially. There is also a press in sleeve that I machined for the top of the strut housing. |  |  |  08-20-2013, 07:37 PM 08-20-2013, 07:37 PM | #17 | | Senior Member Join Date: Feb 2007 Location: Fl Posts: 1,353 |

Very impressive work! __________________

SUPPORT 318ti.org! CLICK THE LINK ABOVE!

Hosting a forum like this is not free. 318ti.org is one of the best BMW forums on the web because it is member supported, not vendor supported. The cost to become a Supporter is a nominal $10.00... A YEAR! DO IT! NOW!

www.BimmerBum.com ALL NEW!

318ti Specific Parts For Sale

www.facebook.com/BimmerBum

BMWCCA #132203

95 318ti Club Sport

98 318ti Active S50 Swap

|  |  |  08-24-2013, 03:43 PM 08-24-2013, 03:43 PM | #18 | | Member Join Date: Jun 2008 Location: Utah Posts: 62 |

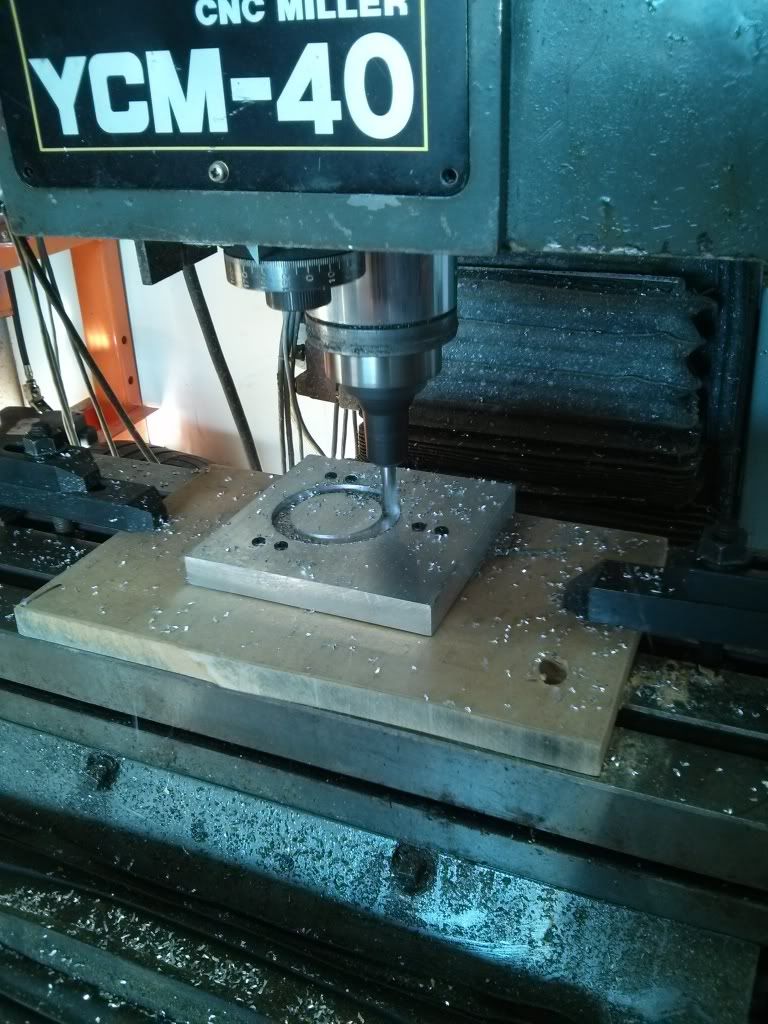

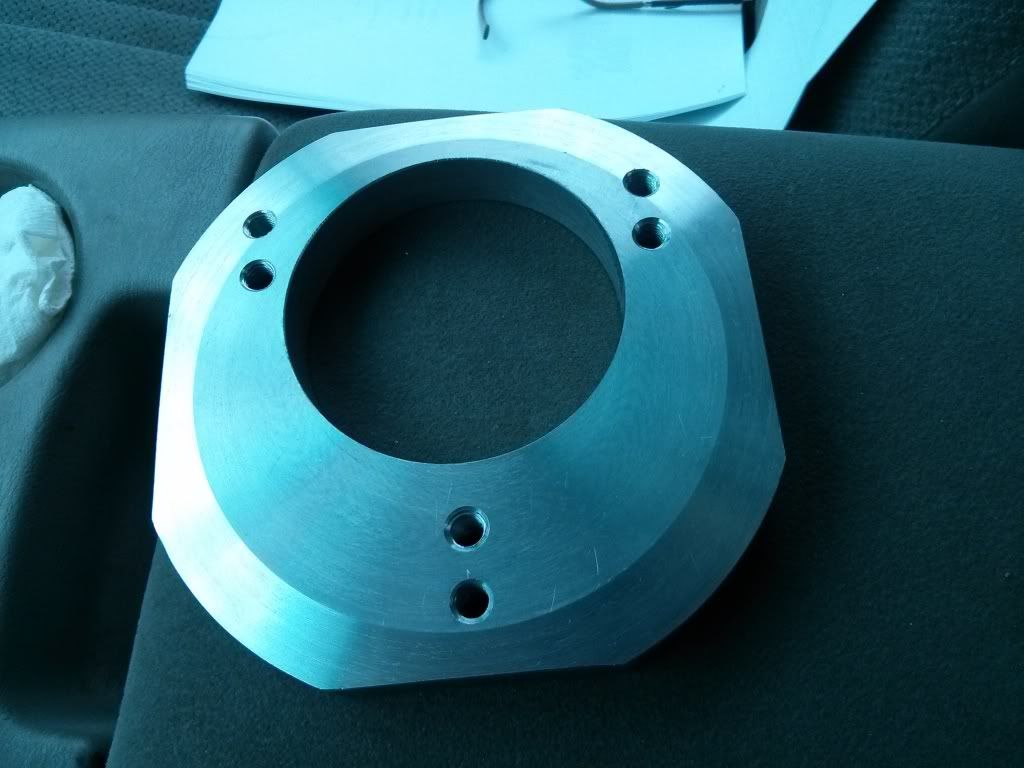

CNC milling out some spacers to correct the Caster  Finished up   Full droop  Rough ride height  The tire clears the fender now and now I can add a tender spring in the future to get down to the final ride height. I should have the front all together this weekend. The Ireland camber and toe plates are welded up in the rear but I want to get the subframe blasted and powder coated before it goes back in. I think I'm going to order up a caster/camber gauge and do my own alignment. I have also tracked down lines to eliminate the ABS module and I've got a plan to deal with the brake bias issues I may run into. |  |  |  08-28-2013, 09:43 PM 08-28-2013, 09:43 PM | #19 | | Senior Member Join Date: Aug 2008 Location: Globally Posts: 1,162 |

Nice work, those look decent and offer added support the to strut tower. I for got I had some E36 Struts alreat modified to take a shortened Koni strut with a E30 style upper.  Now to just find some strut inserts |  |  |  08-28-2013, 10:42 PM 08-28-2013, 10:42 PM | #20 | | Member Join Date: Jun 2008 Location: Utah Posts: 62 |

There aren't really very many Bilstein inserts to even choose from. If you search around in the part number system, it gets to be fairly straight forward to picking out the inserts. From there, you can call Bilstein and they will give you extended and collapsed lengths along with body length. The 36mm stuff I believe all uses the same size tubes on the inserts so it will be 1.81" OD. They also have some 30mm inserts, but I'd rather have the larger load bearing tube of the 36mm. Bilstein also released unfinished 46mm struts this year for rally applications. These are likely what I'll use on my EVO setup.

Another option would be shortening the body and shaft on the E36 Sports, removing the spring perch and cutting the body for a circlip. This is something that you could likely just pay them to do and it likely adds about $150 per shock. Now you are close to $400 a strut though.

I considered using something like the E30 gland nut but the press in sleeve will hopefully work out well. The issue I would have however is that it will never come apart now. Just for good measure, I added some JB weld in a couple strategic places to ensure it is rock solid.

I did design the sleeve in such a way that I can remove the linear bearings though in the future and will be able to rebuild the entire strut if needed.

I meant to assemble everything without the spring installed and see just how much of the travel I can use before stuff starts running into each other. I'm thinking I will likely have at least 1" of the upper shaft that will not be used though. If so, I'll likely modify the strut insert with a shrader valve to make it rebuildable in the future. I'm betting I have it back apart and add a helper spring and a shorter main spring within the year though. I'm thinking it likely would be low enough for my wants after I modify the spindles.

Last edited by 03whitegsr; 08-28-2013 at 10:45 PM. |  |  |  10-31-2013, 04:32 PM 10-31-2013, 04:32 PM | #21 | | Member Join Date: Jun 2008 Location: Utah Posts: 62 |

I got the car done and did my own alignment back in September. Thought I'd follow up here. Doing an alignment on some stands I built to level the car while getting it up high enough to adjust things without having to jack the car up. Also long enough to roll the car back and forth on to settle the suspension after an adjustment.  Final ride height.   This is the lowest the rear will go with the 5" 950lb springs. I'm considering changing to a coilovers setup just so I can add some helper springs. Right now, the rear droop travel is terrible. How it drives... I made it to one autox event right after I got it together for a stress test. I wanted to see how it did without any sway bars at all. Turn in was remarkable, the front simply went where ever I pointed it. The rear on the other hand wanted to go straight on corner entry... And mid corner... And, well always. It was crazy loose and slowed me down greatly. I messed with tire pressures and improved it slightly but at the end of the day, it was still too loose. While on the stock suspension, I knew what it was going to do and I felt comfortable tossing it to the absolute limit, now I had to gently try to bring it up to maximum grip levels. It was a drift car... But that's not what I'm after. I got home and put the stock front sway bar back on. On the street, it feels a lot better now but I'm not sure how it's going to behave at the limit. Adding the front bar killed how razor sharp the initial turn in was though. I'll have to play with toe some to see if I can get some of that quick turn in back. Ride quality, I need to change the rear damping. The linear piston is just too much on the street. Low speed feels good but it's way too much high speed damping. The front feels good though. Firm and planted on low speed stuff and not to harsh thanks to the digressive compression valving. Way forward I'm going to modify the stock front sway bar to make it adjustable and add adjustable end links and poly bushings. Hopefully that will be enough to make it competitive next year. The car was showing great potential as the grip was massive on the stuff I could build the grip up slowly on. If I can sort out the balance, I think it's going to do reasonably well. I'll be picking up some new spindles and I'll likely make a jig to modify them. The roll center height isn't all that bad at the current ride height so it will likely be about a 1" change to the balljoint mount. Adjust the tie rod height to correct bumpsteer and then shorten the steering arm to quicken the steering ratio as the ~15:1 ratio is painfully slow. I'll try and knock it down to the 13:1 range however I'll have to mess with it as I don't want to kill the Ackerman angle while doing it. I'll have to add a rack stop as well. Once the current tires wear out, I'll be putting on some 245/40/17 tires, something similar to the R-S3 tires I currently have. I'll likely get 3 full summers out of them though and around 25 auto x events with probably 15k miles. |  |  |  10-31-2013, 05:05 PM 10-31-2013, 05:05 PM | #22 | | Senior Member Join Date: May 2013 Location: Morgan Utah Posts: 214 |

Cool update, thanks  I have never had the machine tools or experience running them to do what you are doing so I am very impressed and interested in all this fun you are having  Glad you fully understand the difference between lowering a car for looks and doing it right for real handling, I drives me nuts seeing overly lowered cars that handle and ride like crap driven by those that are seemingly clueless about what they have done! With high spring rates you obviously know about less sway bar being needed, it is only a fine tuning tool when all else is done right, why I went the easy way and bought the infinitely adjustable CG front sway bar so I can tune it well but am running less spring rate as this has to be a fairly comfortable car on the road. I am going to try going without a rear, then stock rear with teflon lined adjustable links, beefed up mounts, etc and it not enough bar then the MZ bar. Lowering the rear using coilovers will require some serious upgrading of the mounting points for the top of them, I was looking at this and decided I would end up building an X brace tying it all together and to the floor but decided since my car has to be an all season car I am going to keep the ride height higher so springs worked out in the stock location. With coilovers it would be a pretty easy task to modify the mounting of the subframe and diff rear mounting point to lower the car more while keeping the geometry correct. I was going to do this on my 95M3 race car as had tubular front control arms with geometry correction adjustments build in. I am going to make my own brace between the bottoms of the subframe mounts, tubular, it will weight less and cost practically nothing. First I am going to see if I can triangulate the stock mount locations on each side, if I can tie it to the body there, weld a plate on etc, less weight and less stuff in the middle under the car in the wind. I have dimple dies to make pretty parts with, lighter, stronger, less weight. If I come up with a good design I will share it with you  I think I will be quite happy with the CG hybrid street/track SA coilover front, shock/spring rear setup but will be keeping an eye on what you are doing, in case I want to move up and you make some available  I have the car all apart now, only the glass and main harness still in it, stripping out all the junk I can, reworking the hatch floor to fit the battery, ultra low weight audio system, tool kit, sound deadening with my light weight techniques, gusseting, etc, anything that needs it....I have to build a dual ear mount for the diff as well...... I am considering notching the rear subframe with a section of 4" pipe to run the 3" exhaust through, cutting about 60% out of the subframe, welding in the pipe, added bracing to the bottom, it would be plenty strong and get the big exhaust up out of the wind, less danger of hitting anything, less bends for better flow...... You are welcome to come up to Morgan and check it out, anytime  Have a great Holloween! (we are giving out Organic Honey/Cocoa/pom or mint flavor treats, the only incredients in the healthy candies, a bit expensive but we want to let the kids know there are treats that are healthy for them) Keep up the cool work buddy! Rick 801-829-4997 |  |  |  10-31-2013, 05:24 PM 10-31-2013, 05:24 PM | #23 | | Senior Member Join Date: Feb 2007 Location: Fl Posts: 1,353 |

Very nice. Hats off to you for not going conventional. __________________

SUPPORT 318ti.org! CLICK THE LINK ABOVE!

Hosting a forum like this is not free. 318ti.org is one of the best BMW forums on the web because it is member supported, not vendor supported. The cost to become a Supporter is a nominal $10.00... A YEAR! DO IT! NOW!

www.BimmerBum.com ALL NEW!

318ti Specific Parts For Sale

www.facebook.com/BimmerBum

BMWCCA #132203

95 318ti Club Sport

98 318ti Active S50 Swap

|  |  |  10-31-2013, 06:04 PM 10-31-2013, 06:04 PM | #24 | | Senior Member Join Date: May 2013 Location: Morgan Utah Posts: 214 |

I am installing an M3Z steering rack to quicken things up but I see you are modifying the location of the tie rod mounts to do the same thing. I had the SSR tubular control arms with that designed in so the rack may of been a bit to much quicker with both being used. I was going to suggest the rack until I saw what you are doing, good thing  I happen to have a set of steering limiters from TMS if you need a set let me know. |  |  |  10-31-2013, 07:08 PM 10-31-2013, 07:08 PM | #25 | | Member Join Date: Jun 2008 Location: Utah Posts: 62 |

Nice man. Yeah, I'm planning on either the BMW Motorsports brace up front or making my own. For the price and the lack of time I have though, I'm likely to just get the BMW brace.

For the back, I think I can pull off a pretty sweet xbrace in the car. The rear subframe mounts go all the way through to the interior. I think I can either pin into them or maybe thread them for a mount point. Cross brace from the shock tower across the car down to these mounts. Then a traditional straight bar from one shock tower to the other. With the subframe essentially closing the lower section, it will be partially triangulated. I either close the sides with another tube or possibly just gusset the center area to avoid the two triangles tip to tip situation. I’ll probably do it out of some 1-1/2" thin wall aluminum tubing to shed weight and yet still be stiff with the large OD. I don't have the rear seat in and putting an xbrace in will only hurt me when I use the car like a truck. It will easily fit about twenty 8' long 2x4s and I had about 500 pounds of concrete in it for a home project recently. It's my mini truck.

I hear you on the shock tower reinforcement and that's why I stuck to the separate spring/shock this time around. But with the high spring rates, it really limits you since you can't really use a helper spring. Right now, even with no rear sway bar, it still wants to lift the inside tire pretty easily. It wouldn't be a huge problem if I had a real LSD but this 25% lock up crap BMW does and the fact it's got 110k miles on it means it does VERY LITTLE to control wheel spin.

If I were to redo the trailing arms, I could likely just pick up the Turner Motorsports J-Stock springs. They are essentially a 900 lb spring with a helper section in them. I just doubt it would get the car down to the ride height I want without changing the spring mount on the trailing arm. I still want to go lower but it's definitely to the point where it's going to take a lot of work to avoid all the geometry issues that come with going lower. Another 3/4" in the rear and 1/2" in the front would be about right. I'd love to go to something like the GRP A stuff where they dropped down to a 12* subframe/arm setup. Right now, the car is too deep into the toe curve and that’s really the best way to deal with it.

Lesson learned though, I would recommend AGAINST the Ireland locking camber kit for the rear. It has a HUGE range of adjustment for the guys wanting to correct a heavily lowered car back to near zero camber. But it is only about 1/8" away from the body of the car, there is no way you could use their camber kit with the subframe bushings that offset the subframe up 12mm. You don’t need the height if you are looking to run 2* or more negative camber either so the added range isn’t doing anything for me. You could use them for toe adjustment though. Honestly though, they are a PITA to adjust and I wish I had gone with the eccentric bolt setup instead.

I'm kind of considering a complete rear suspension swap. The FR-S rear suspension would be pretty awesome as all the mounts are part of the subframe and nothing else ties to the unibody. Build a tubular subframe to adapt it to the 318 unibody for a pretty simple solution. There is going to be nearly unlimited parts for that car too. However, the FR-S track width is 5" wider than the 318ti though and while a wide body sounds fun, I don't see that happening. This would kind of kill the simplicity and handling character of the car too. But if it made it faster... |  |  |  10-31-2013, 07:57 PM 10-31-2013, 07:57 PM | #26 | | Senior Member Join Date: May 2013 Location: Morgan Utah Posts: 214 |

I have a 20' section of 1 3/4" aluminum tubing I was going to make front and rear bumpers out of for my M3 race car, I have to look at the thickness now as do not recall but you might want some of it  Off to the wrecking yard, picking up a dash, dash bars and other misc parts, cheap too! |  |  |  11-01-2013, 06:43 PM 11-01-2013, 06:43 PM | #27 | | Member Join Date: Jun 2008 Location: Utah Posts: 62 |

One last thing, not really suspension related but was part of the changes. As I mentioned, I pulled the ABS. With about $50 in adapters and hardlines, I built up a line setup to replace the ABS module. The factory fittings are 10x1 and 12x1 ISO bubble flares. The 12x1 fittings/adapters were a little more difficult to source.

The 318ti has a staggered master cylinder (23.81mm/20.64mm f/r) to help balance the brake pressures front to rear. Between this and the brake rotor/caliper bias, I came up with 65% front brake bias. Considering the ~53% weight bias, this works out about right by some of the "conventional opinions" of having 10% more brake bias then weight bias.

I haven't done much threshold braking since putting on the front sway bar. On the street though, I have yet to experience rear lock up before the front. I haven't REALLY provoked it with trail braking or anything like that, but for street use, it seems plenty forgiving.

Also, I now have the 15" rims with snow tires on. With the 17s, the ride was as mentioned, firm and controlled. With the snow tires, the tire is the softest part of the suspension and unfortunately, basically undamped. The car is now bouncy on the low-speed body movements because of the sidewall flex. A perfect lesson in how the tire "spring" is in series with the suspension... |  |  |  11-01-2013, 10:51 PM 11-01-2013, 10:51 PM | #28 | | Senior Member Join Date: May 2013 Location: Morgan Utah Posts: 214 |

I have removed ABS from a few cars as well, the last one was FWD and very fast on track I had a bit more rear brake than I preferred as was locking up the rear a bit to much and flat spotting the tires. I installed a Wilwood "bias" adjuster, more correctly a pressure adjuster, on the rear lines after mating them together since originally it was a 4 way system. I only dialed it back a little and it was perfect so left it there from then on. I happen to have one or two of those units if you need one, just thought of that, not the reason I posted the above  Rick |  |  |  11-02-2013, 12:52 AM 11-02-2013, 12:52 AM | #29 | | Member Join Date: Jun 2008 Location: Utah Posts: 62 |

Yeah, there is a Wilwood adjustable proportioning valve that has 10x1 fittings in it for like $60. I actually got a flexible line made for the rear channel just for this purpose. I can simply remove the female-female coupler and toss in the Wilwood piece if I end up needing some rear bias removed. I have a feeling the winter will also give me a good feel for the balance here too. Seems like if it's too rear happy without a lot of weight transfer (due to slick roads), you can guarantee it's going to be even worse when grip comes up. |  |  |  11-03-2013, 04:01 AM 11-03-2013, 04:01 AM | #30 | | Senior Member Join Date: Sep 2007 Location: asdfasdf Posts: 10,002 |

your fab work is really impressive, not many people can say they've made their own coilovers |  |  |  | |

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | | |

Posting Rules Posting Rules | You may not post new threads You may not post replies You may not post attachments You may not edit your posts

HTML code is Off

| | |

|